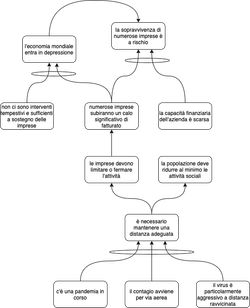

Brief summary of the previous episodes: using a map of objectives we defined what results we want to pursue, as a company, and using cause-effect correlations we created a map of problems and identified the actual causes that negatively affect our system.

Attention: when we talk about "system" we can refer to the company as a whole, but also to any of the "sub-sets" (processes) that compose it. For example, the sales process can actually be considered a system, as well as the order management process or the logistics process. I say this because obviously the analysis of the symptoms and the relative map of the problems can be referred to the individual process, with the only warning of maintaining an overview referring to the “global” objectives.

It may seem like a contradiction, considering that most companies spend about 1/4 of their fiscal year on budgeting with specific goals for each department. Unfortunately, contrary to what you might think, maximizing the results of individual departments is not the same as maximizing the business objective.

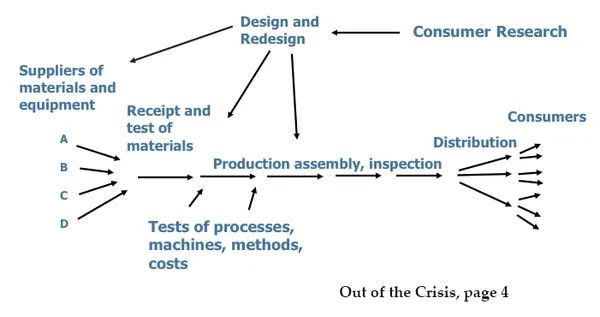

Strange? Let's think about it and make some considerations; if we accept the fact that a company is made up of interdependent processes, we can imagine it as a chain: a series of links (the processes) that all work together aimed at a common result (the corporate mission). And, as is well known, if we subject a chain to stress (i.e. if we put it under tension) it will give way at a specific point — its weakest link.

Now it is clear that optimizing the performance of every single ring is a "non sense" and that instead we should strive in every way to know which is the weak link of our system, also because this represents the "lever point" thanks to which we can significantly increase performance.

So if the "global" goals are clear, consistent and valid for all processes, and we have identified the causes that afflict the system, now is the time to introduce and use a specific tool to treat the constraint (the weak link) that we have identified. ToC suggests using a process called 5FS or Five Focusing Steps, a process that includes the following five steps:

- Identify the constraint, the factor that limits system performance

- Decide how to maximize, how to make the most of the constraint

- Subject each decision to the previous one

- Raise the constraint

- Start over, preventing inertia from becoming the new constraint

As always, we are available to help your people modify the processes to increase the performance of your company. To the next episode, with the 5FS cycle!