Project management is a complex set of tasks, resources, and deadlines. For decades, traditional project management methodologies, often rooted in PERT and Critical Path Method (CPM), have been the go-to. However, in the real world, projects frequently run late, go over budget, and fail to deliver on their promises. This is where Critical Chain Project Management (CCPM) steps in, offering a revolutionary approach designed to address the inherent flaws of traditional methods and deliver projects faster and more reliably.

What is CCPM?

At its core, Critical Chain Project Management is a methodology developed by Dr. Eliyahu M. Goldratt, the creator of the Theory of Constraints (TOC). Unlike traditional approaches that focus on managing individual task durations and their dependencies, CCPM shifts the paradigm to managing the flow of the entire project, with a keen eye on resource availability and the inherent uncertainties of project work. It acknowledges that people tend to inflate task estimates (safety time), then procrastinate until the last minute (Student Syndrome), and that variability at one stage can fluctuate through the entire project (Parkinson's Law and the "Bullwhip Effect" – a phenomenon we'll explore in more detail in a separate post).

CCPM aims to protect the project's overall completion date by identifying the "critical chain"—the longest sequence of dependent tasks that also considers resource availability. This critical chain is often different from the critical path because it takes into account potential resource contention.

The Problem: Why Traditional Project Management Fails

Let's face it, traditional project management, while offering a structured framework, often struggles with a few persistent issues:

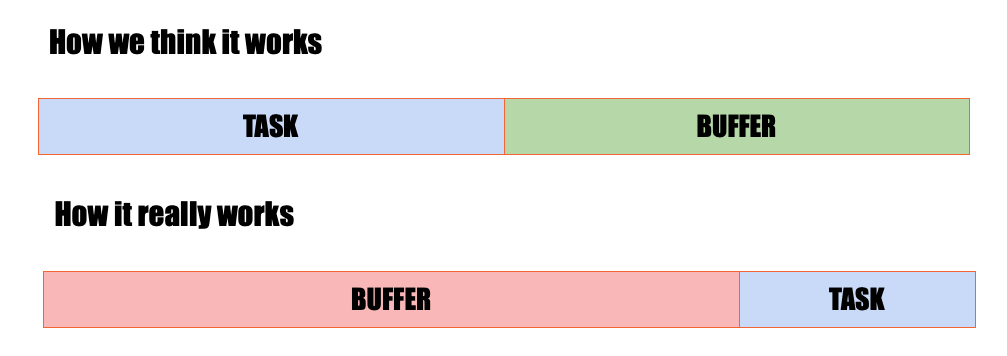

- Individual Task Safety: Project managers and team members, often unconsciously, add "safety time" to their individual task estimates. They want to ensure they finish their tasks on time, so they buffer their estimates. While this seems prudent for an individual task, when aggregated across an entire project, it creates a massive amount of hidden, unused safety time.

- Student Syndrome: With this hidden safety time, people tend to delay starting a task until the last possible moment, consuming much of the buffer they built in.

- Parkinson's Law: "Work expands so as to fill the time available for its completion." If a task is estimated to take five days, it will likely take five days, even if it could have been done in three. The excess time is often filled with non-critical activities or simply becomes wasted.

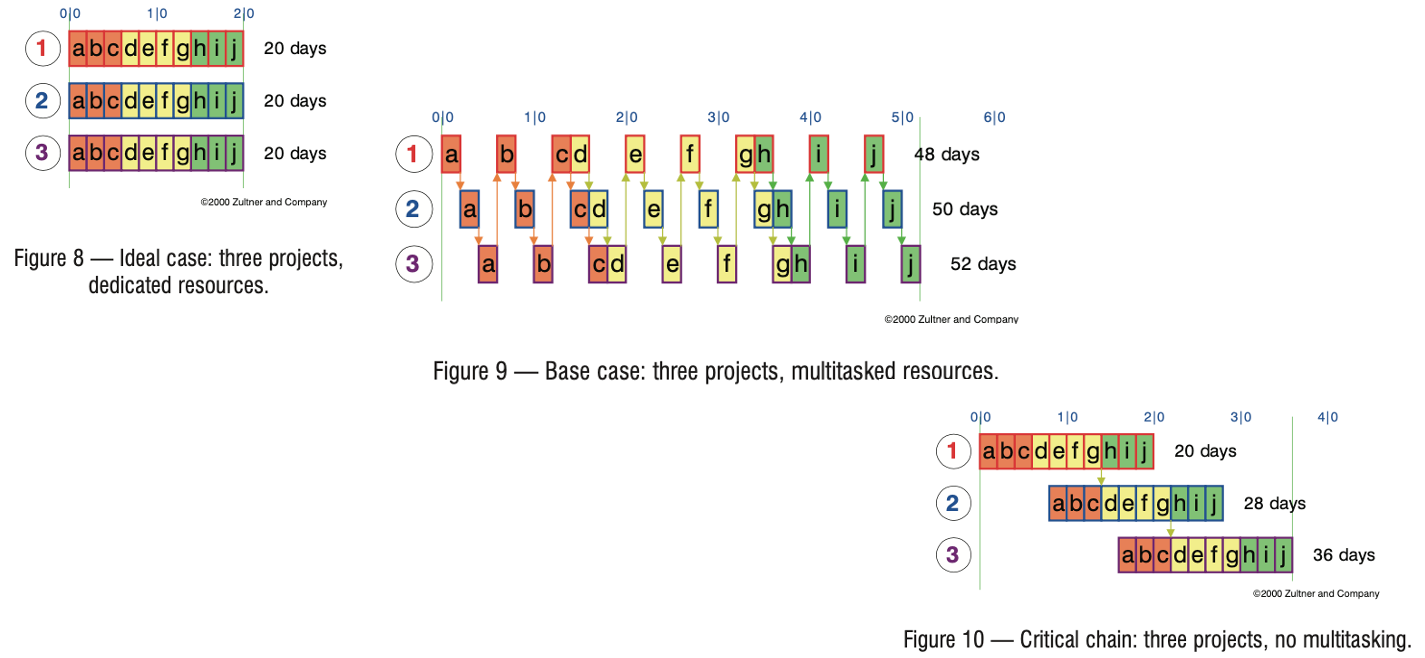

- Multitasking and Resource Contention: In an effort to keep everyone busy, resources are often assigned to multiple projects or tasks simultaneously. This leads to frequent task switching, reduced efficiency, increased lead times, and further delays.

- Lack of Project-Level Protection: Traditional methods often don't provide adequate mechanisms to protect the overall project schedule from the inherent uncertainties and variability of individual tasks. Delays in one task frequently cascade and impact subsequent tasks, leading to the entire project slipping.

- The "Bullwhip Effect" (or variability amplification): Just as in supply chains, variability at a micro-level (individual task delays) can be significantly amplified as it moves up the project chain, causing larger and larger disruptions further down the line. This effect often means small delays become big project overruns.

These ingrained habits and systemic issues create a culture of missed deadlines and budget overruns. Traditional PM often focuses on "on-time, on-budget" for individual tasks, which can paradoxically lead to the project being late and over budget.

The Solution: CCPM Principles

Critical Chain Project Management offers a refreshing alternative by challenging these deeply ingrained habits and focusing on system-wide optimization. Here are its core principles:

- Focus on the Critical Chain:

- Identify the Critical Chain: This is not just the longest path of tasks (critical path) but the longest sequence of dependent tasks and resource dependencies. It's the bottleneck sequence that truly dictates the project's minimum completion time.

- Prioritize: Once identified, all efforts are focused on ensuring the tasks on the critical chain progress without delay.

- Aggressive but Realistic Task Estimates (No Individual Safety Time):

- Remove Hidden Buffers: Team members are asked to provide their "focused duration" estimates – how long a task would take if there were no interruptions, no need for personal safety, and 50% certainty of completion. This eliminates the individual safety time.

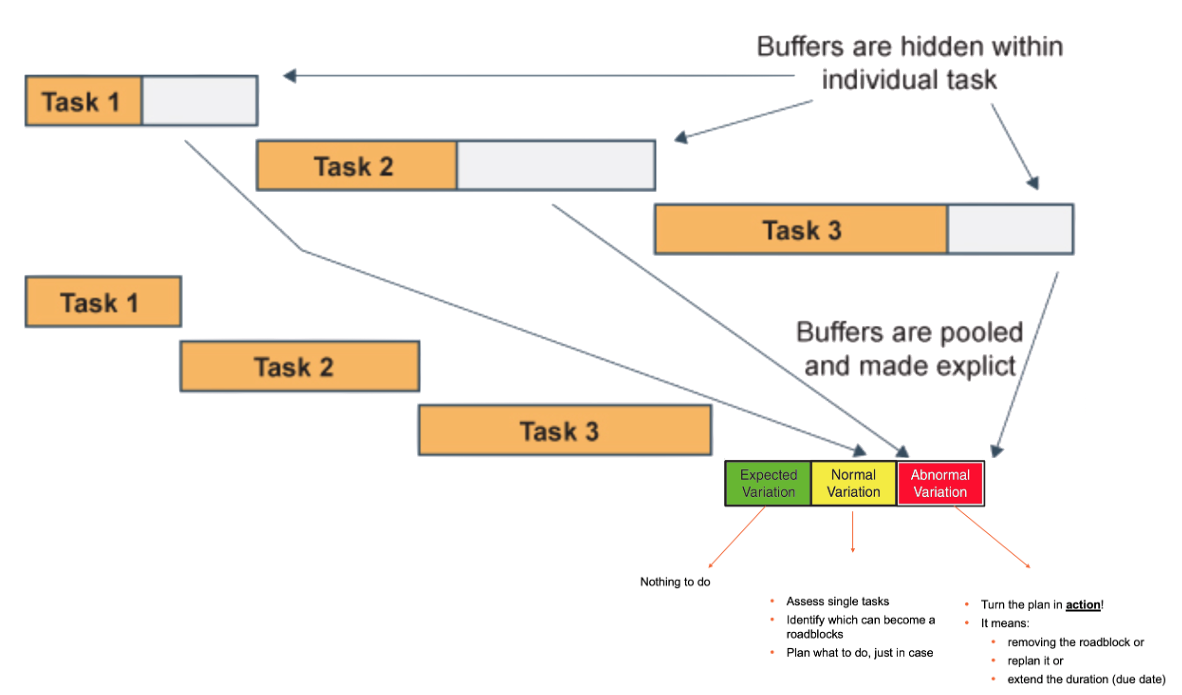

- Collect and Pool Buffers: The removed individual safety time isn't discarded; instead, it's aggregated and pooled into strategic project buffers.

- Strategic Project Buffers:

- Project Buffer (PB): Placed at the very end of the critical chain, this buffer protects the overall project completion date from delays originating on the critical chain.

- Feeding Buffers (FB): Placed at the end of non-critical chains that "feed into" the critical chain. These buffers protect the critical chain from delays on feeding paths. If a feeding path runs late, it consumes its feeding buffer, but ideally, it won't impact the critical chain.

- Resource Buffers (RB): These are not time buffers but rather alerts or placeholders positioned just before a critical chain task requires a specific resource. They signal to that resource to be ready and available, preventing delays due to resource unavailability.

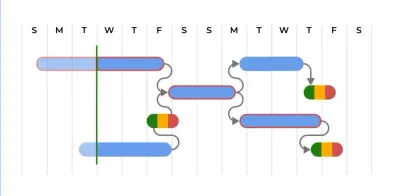

- Buffer Management: Buffers are not "extra time" to be used. They are monitored continuously. The rate at which buffers are consumed provides an early warning system. If buffers are depleting too quickly, it signals a problem that needs immediate attention.

- Full Kit and Relay Race Mentality:

- Full Kit: Before a task on the critical chain begins, all necessary inputs, information, and resources must be fully available ("full kit"). This prevents tasks from starting only to stop due to missing components.

- Relay Race: The project is treated like a relay race. The focus is on quickly passing the baton from one task to the next, not on individual task optimization. The goal is to finish the project as quickly as possible, not to finish each task as quickly as possible.

- Focus and Elimination of Multitasking:

- Single-Tasking: Resources assigned to critical chain tasks are encouraged, wherever possible, to work on only one task at a time until it's complete. This reduces setup times, increases focus, and accelerates task completion.

- Resource Leveling: CCPM inherently includes robust resource leveling to avoid overloading critical resources.

- Throughput-Oriented Measurement:

- Project Throughput: The ultimate measure of success is the rate at which projects are completed and generate value. CCPM optimizes for overall project throughput rather than individual task efficiency.

Tools & Techniques for CCPM

Implementing CCPM effectively requires specific tools and a shift in project management practices:

- Critical Chain Software: Specialized software (e.g., Lynx by A-Dato, Project Management software with CCPM logic) is invaluable. These tools can identify the critical chain, calculate buffer sizes, track buffer consumption, and manage resource loading.

- Buffer Reporting: Regular reports showing buffer consumption status (e.g., green, yellow, red zones) are crucial for proactive management.

- Go/No-Go Checklists (Full Kit): Formal checklists before starting critical tasks ensure all prerequisites are met.

- Daily Stand-ups / Buffer Reviews: Brief, focused meetings to review critical chain progress and buffer status, identifying and resolving impediments quickly.

- Visual Management Boards: Whiteboards or digital boards can visually track critical chain tasks, resource assignments, and buffer levels.

- Training and Cultural Shift: This is perhaps the most important "tool." Teams need to be trained on the principles of CCPM, understand why individual safety is removed, and embrace the "relay race" mentality. This requires a significant cultural shift from individual task protection to collective project protection.

Case Example: Implementing CCPM in a Small Italian Manufacturing Company

Let's imagine "Meccanica La Veloce," a made up small, family-owned Italian company specialising in custom-built, high-precision industrial machinery. They have a reputation for quality but often struggle with meeting promised delivery dates, leading to frustrated clients and missed opportunities. Their traditional project management approach, while thorough, was constantly plagued by:

- Engineering designs taking longer than expected.

- Delays in procuring specialized components from suppliers.

- Assembly teams waiting for parts or drawings.

- Testing phases revealing issues that required rework, pushing back final delivery.

Their latest project, a complex pasta-making machine for a niche market, was already showing signs of trouble. The initial estimate was 18 weeks, but the project manager's gut feeling (and historical data) suggested it would be closer to 24.

Here's how Meccanica La Veloce decided to apply CCPM:

- Task & Resource Analysis: The project team mapped out all tasks, their dependencies, and the resources required (design engineers, procurement specialists, machinists, assembly technicians, quality control). They identified key bottlenecks, such as the single senior design engineer and the highly specialized XYZ machine.

- Aggressive Estimates: Each team member was asked to provide a 50% probability estimate for their tasks. For instance, the design engineer, who previously estimated a specific module design at 3 weeks (including safety), now estimated it at 1.5 weeks. The cumulative "safety time" removed from individual tasks across the project was significant.

- Identifying the Critical Chain: Using a CCPM-enabled software, they identified the critical chain. It wasn't just the design-build-test sequence, but specifically factored in the limited availability of the senior design engineer and the XYZ machine, which were shared across multiple high-priority tasks.

- Inserting Buffers:

- Project Buffer: A 3-week project buffer was placed at the end of the project, protecting the 18-week target.

- Feeding Buffers: Feeding buffers were added for non-critical paths, such as the procurement of standard components and the calibration of auxiliary sensors. If the sensor calibration ran late, it would consume its feeding buffer but wouldn't immediately impact the critical machine assembly, meanwhile giving early warning in case of issues.

- Resource Buffers: A resource buffer (in the form of an alert and prioritized task queue) was placed before the XYZ machine's critical operations, ensuring the machine operator was ready and materials were available. Another was set for the senior design engineer before a critical design review.

- Full Kit & Focus:

- For the main assembly phase, a "full kit" check was implemented. Assembly wouldn't start until all custom-machined parts, standard components, and final design drawings were physically present and verified.

- The lead assembly technician, previously prone to multitasking, was assigned exclusively to the critical chain assembly tasks, minimizing context switching.

- Buffer Management & Daily Reviews:

- The project manager instituted daily 15-minute stand-up meetings, focusing on critical chain tasks and buffer consumption. "How much buffer have we consumed as of today?" became a key question.

- Early in the project, they noticed the "Design Review" feeding buffer was depleting quickly. This warned about a potential problem with the availability of a specific external consultant. The project manager was able to proactively escalate and secure the consultant's time, preventing a delay to the critical design phase.

- Later, during the testing phase, an unexpected issue with a custom sensor caused a delay. The project buffer started to turn "yellow", prompting the team to quickly reallocate resources to resolve the sensor issue, bringing in an external specialist sooner than planned, thus protecting the final delivery date.

Outcome:

While the project still encountered challenges (as all projects do), Meccanica La Veloce delivered the pasta-making machine in 19 weeks – one week into their 3-week project buffer. This was significantly better than their historical average and the initial pessimistic estimate. The client was delighted, and Meccanica La Veloce gained valuable experience and confidence in CCPM. They realized that by focusing on flow, protecting the overall project, and using buffers as a management tool, they could achieve more predictable and faster project delivery. This success also laid the groundwork for further process improvements, understanding that "5 Common Mistakes in Applying Critical Chain Project Management" would need to be addressed as they scaled its use.

Learn More About Our Consulting Approach

Are your projects consistently late, over budget, or struggling with resource contention? Do you want to move beyond the frustration of traditional project management and achieve more reliable, faster project delivery?

At Menicucci & Associati, we specialize in helping organizations like Meccanica La Veloce implement and optimize Critical Chain Project Management. Our consulting approach focuses on:

- Customized Implementation: Tailoring CCPM principles to your specific industry, project types, and organizational culture.

- Training & Mentorship: Equipping your teams with the knowledge and skills to embrace and excel with CCPM.

- Process Optimization: Identifying and eliminating bottlenecks, improving flow, and maximizing project throughput.

- Sustainable Change: Guiding you through the cultural shift required for long-term CCPM success.

Ready to transform your project delivery and achieve your strategic goals with greater predictability? Contact us today for a free consultation and discover how CCPM can revolutionize your project management capabilities. Let's work together to make your projects not just successful, but predictably and consistently so.