For many companies, inventory is an area with significant (potential) for improvement. Whether it’s a manufacturing company or a distributor, increasing product turnover can have a big impact on the bottom line — both in terms of costs and revenues.

On the cost side, it can help solve space issues, reduce tied-up capital (working capital), and even lower tax exposure — since the tax authorities treat inventory as potential income. On the revenue side, it’s clear that stock-outs directly lead to missed sales.

And the impact can be substantial: moving from an average turnover of 6 times a year to 12 could, depending on revenue and gross margin, result in a very pleasant surprise.

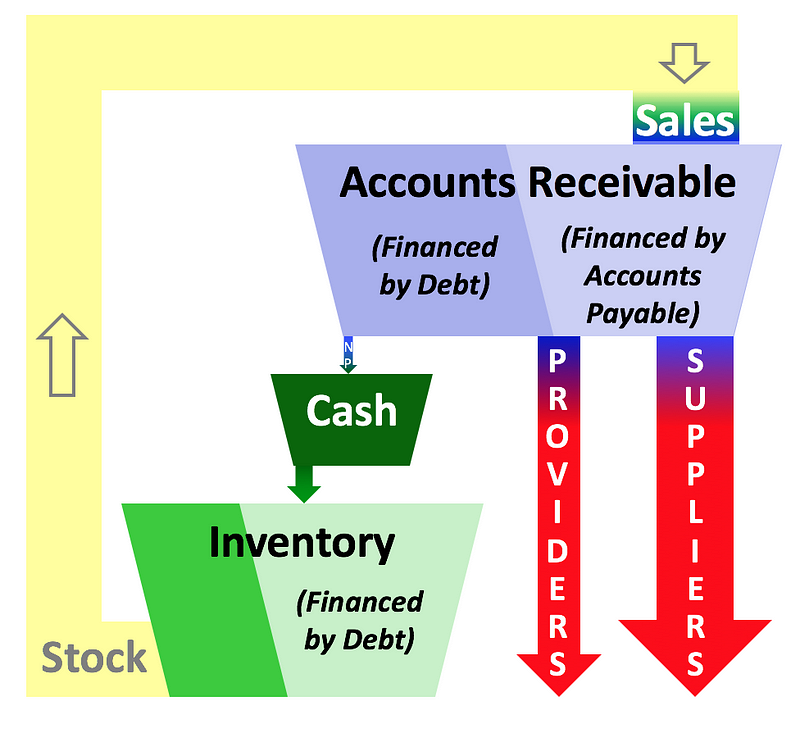

Our methodology involves analyzing the process from a systemic perspective (see image), focusing on cause-and-effect relationships, and then identifying the most suitable solution. This approach delivers immediate results while laying the foundation for a continuous improvement process.

Want to learn more and see how your company could benefit? Click here — no strings attached